|

Shanghai Wedo Industry Co.,Ltd

|

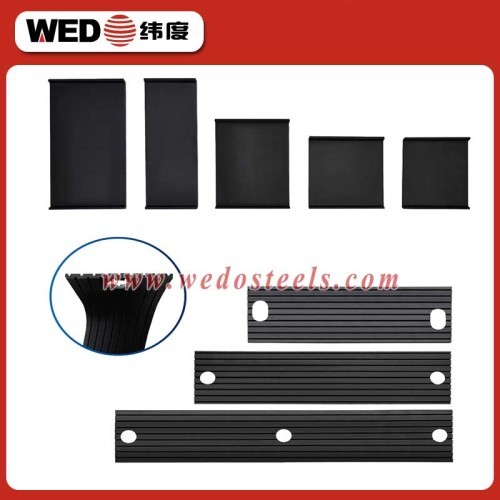

Anti-vibration railway rubber mat

| Price: | 5.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rail pads are elastic polyurethane mats which are interposed between steel rails and tie sleepers .

Rail pads are elastic polyurethane mats which are interposed between steel rails and tie sleepers to protect the sleeper top from under the despite of any vertical movements of the latter.In Additon, the reason why rail pads made up of rubber or plastic is to dempen the shocks of vibration of passing train.

A rail pad is essential in reducing shock and vibration in a rail system. The pad laid under the rail to ensure:

· Load distribution over a larger surface

· Elimination of load concentration and the resultant fatigue stresses

· Centering of loads on the supporting element

· Absorption of uneven contact surfaces between rail and support

· Reduction of noise and vibration

· Sealing between the bottom of the rail and the top of the support

· Reduction of wear of the rail and its support

We have developed a range of highperformance elastic rail pads for stiffness requirements and various application areasfrom trams through standard gauge railways to heavy haul lines, especially those for E-type rail fastening systems and SKL type rail fastening systems with material of HDPE/EVA/Rubber, with following properties respectively.

Check Item | STANDARD | |||||||||||

SAZW5 | SAZW6 | SAZW7 | SAZW8 | SAZW9 | SAZW10 | SAZW11 | SAZW12 | SAZW13 | SAZW14 | SAZW15 | SAZW16 | |

Length(mm) | 140±1.2 | 158±1.2 | 125±1.2 | 165±1.2 | 140±1.2 | 140±1.2 | 274±1.2 | 180±1.2 | 194±1.2 | 170±1.2 | 245±1.2 | 200±1.2 |

Width(mm) | 50±0.8 | 58±0.8 | 160±1.2 | 138±1.2 | 29±0.5 | 57±0.8 | 149±1.2 | 122±1.2 | 60±0.8 | 80±0.8 | 160±1.2 | 148±1.2 |

Thickness | 6±0.2 | 4±0.2 | 4±0.2 | 6±0.15 | 6±0.2 | 6±0.2 | 4±0.2 | 4±0.2 | 4±0.2 | 4±0.2 | 4±0.2 | 4±0.2 |

Glass Fiber % | 35+2 | |||||||||||

Tensile Strength (Mpa) | >170 | |||||||||||

Bend Strength (Mpa) | >238 | |||||||||||

Flexural Modulus (Mpa) | >8000 | |||||||||||

Impact strength (without notch ) (KJ/m²) | >80 | |||||||||||

Rockwell Hardness (HRR) | ≥110 | |||||||||||

Density (g/cm³) | 1.35-1.4 | |||||||||||